Know Your Mix

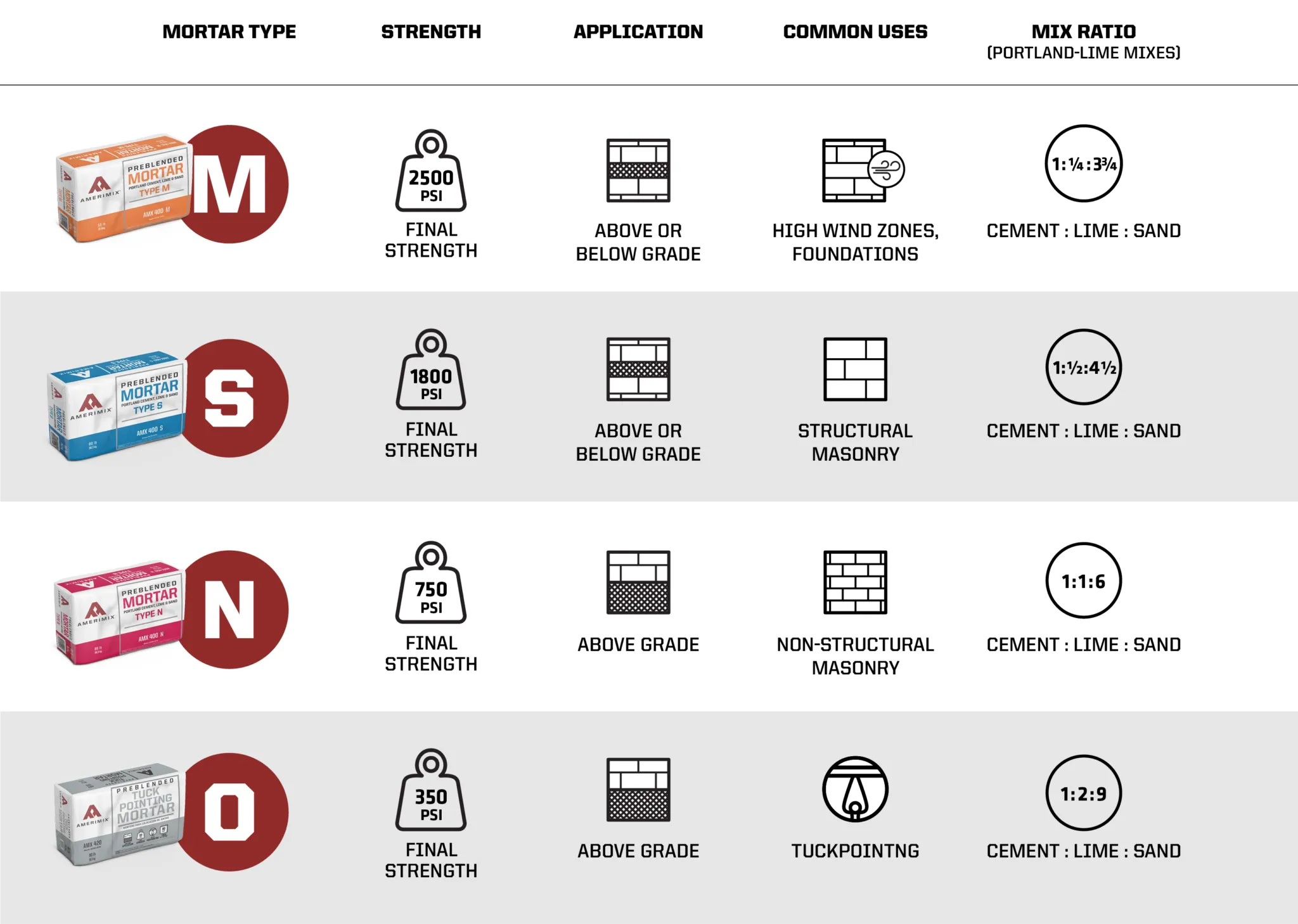

Mortar Types - Type N, S, M, O

Mortar is a product composed of masonry cement (or Portland cement and lime) and mason sand. When water is mixed in with this product, the cement is activated. Whereas concrete can stand alone, mortar is used to hold together bricks, stones, or other building materials. Mortar doesn’t need the strength of concrete; however, it needs good bonding characteristics.

Mortar comes in a few standard types – N, S, M, and O. Each mortar type has its own unique characteristics and common application types. With Amerimix pre-blended mortar types you have the option to request an onsite demo or request a color card to see which mortar type best fits your project.

By using a pre-blended mortar you’ll save also time and money and not have to worry about field mixing. Though the recipe is simple, field mixing is inherently inconsistent because the ingredients are measured by eye – not exactly a recipe for accuracy. This inaccuracy is compounded by the varying amount of moisture in the sand, which can further throw off the mix due to a phenomenon called “sand bulking”.

Sand Bulking is when sand is delivered in a truck and stored outside and has a variable amount of moisture content. This moisture binds to the individual grains of sand and actually increases its volume until the moisture content exceeds 7% and the bulking effect collapses. This means that a cubic foot of damp sand may be anywhere between 1 cubic foot and .7 cubic feet – a major difference in mix ratio.

Not sure how much mortar you’ll need? Use our mortar calculator to get an estimate.

Type N Mortar

Type N mortar has 750-psi compressive strength which is suitable for above-grade brick or soft stone. Type N Mortar is commonly used for above-ground, exterior, interior, load-bearing, and soft stone masonry applications.

Amerimix Type N mortar is available in AMX 400 series, 500 series, AMX 405 & 505C, and AMX WRM 410 & 510RB.

Type S Mortar

Type N mortar is very similar to Type S mortar however the main difference between type N and Type S mortar is compressive strength. Type S mortar contains more Portland cement, giving it a 1,800-psi compressive strength – making it strong enough for brick or block above or below-grade applications. This means that Type S mortar is stronger than Type N mortar.

Type S mortar is a general-purpose mortar suitable for nearly every masonry project due to its compressive strength - 1,800 psi. Common applications of Type S mortar are above or below-grade applications, patios, retaining walls, masonry foundations, and sewers.

The drying time for Type S Mortar is highly dependent on environmental factors like temperature, wind, humidity, and sunlight exposure. However, curing time is consistent with all mortars reaching their full strength within 28 days.

Type M Mortar

Type M mortar has a high-strength formulation suitable for heavy-duty applications, including below-grade masonry projects. Its 2,500-psi strength rating also makes it ideal for use in high-wind or seismic zones. Type M mortar is the strongest mortar type, making it well-suited for heavy loads, masonry below-grade applications, foundations, retaining walls, and driveways.

The primary difference between Type M and Type S mortar is compressive strength. Type M mortars deliver 2,500 psi compressive strength, whereas Type S mortars deliver around 1,800 psi compressive strength. While either Type S or Type M mortars can be suitable for masonry projects in seismic zones, many engineers prefer specifying Type M mortar for its ability to provide the maximum resistance to lateral loads that may be experienced in an earthquake.

Type M mortars are somewhat less workable and less adhesive than Type S and N mortars due to their increased cement content. However, Amerimix Type M mortars are formulated for maximum adhesion without sacrificing strength and are engineered to deliver maximum board life.

The drying time on Type M mortar will vary based on environmental conditions however full cure is typically reached after 28 days.

Type O Mortar

Type O mortar is a specialty, low-strength mortar used primarily used in the interior, non-load-bearing applications or for tuckpointing repairs. Type O mortar has a strength of 350 psi making it highly workable, but only suitable for select applications.

Type O mortar is frequently used for non-structural repairs or “re-pointing” of existing masonry work due to its workability. It is important to match mortar strength to block strength in order for a wall to perform correctly. Mortar is typically designed to be weaker than the masonry it supports so that any cracking propagates through mortar joints instead of the block itself, which could be a structural concern. Low-strength mortars, such as Type O, are therefore recommended when low-strength masonry units, such as sandstone, are being used.

The difference between Type O mortar and other mortars is its compressive strength. Type O mortars are typically around 350 psi, compared to Type N mortars at 750 psi, Type S mortars at 1,800 psi, and Type M mortars at 2,500 psi.

Drying time on Type O mortar will vary based on environmental conditions like the other mortar types however full cure is reached after 28 days.

Mortar Type PSI Strength Chart

| Mortar Type | PSI Strength |

| Type M | 2,500 PSI |

| Type S | 1,800 PSI |

| Type N | 750 PSI |

| Type O | 350 PSI |